MEV®-8 Insulation Monitoring Equipment for Medical IT Systems

The MEV®-8 Insulation Monitoring System monitors the safety of electrical equipment in Group 2 medical premises, such as operating rooms and ICUs, where defective electrical equipment can cause serious incidents. For over 44 years, our MEV systems have saved lives and protected valuable equipment in Finnish hospitals.

We have developed our newest fifth-generation MEV-8 equipment in collaboration with hospital engineers and international partners. The latest equipment fully complies with all national and international regulations, including IEC 60364-7-710 and IEC 61557-8, which mandate insulation monitoring in medical IT systems.

In addition, the MEV-8 system offers a unique feature: Protective Earth (PE) conductor continuity monitoring with the LC 8 Line Controller. While not yet a compulsory requirement, this safeguard is recommended by international standards. By continuously verifying grounding integrity, it provides an extra layer of protection, ensuring equipment remains correctly earthed even during faults or power interruptions.

The MEV®-8 Insulation-level Monitoring System – How it works

- The electric power network of the operating room is separated from the electrical grid by a medical insulation transformer.

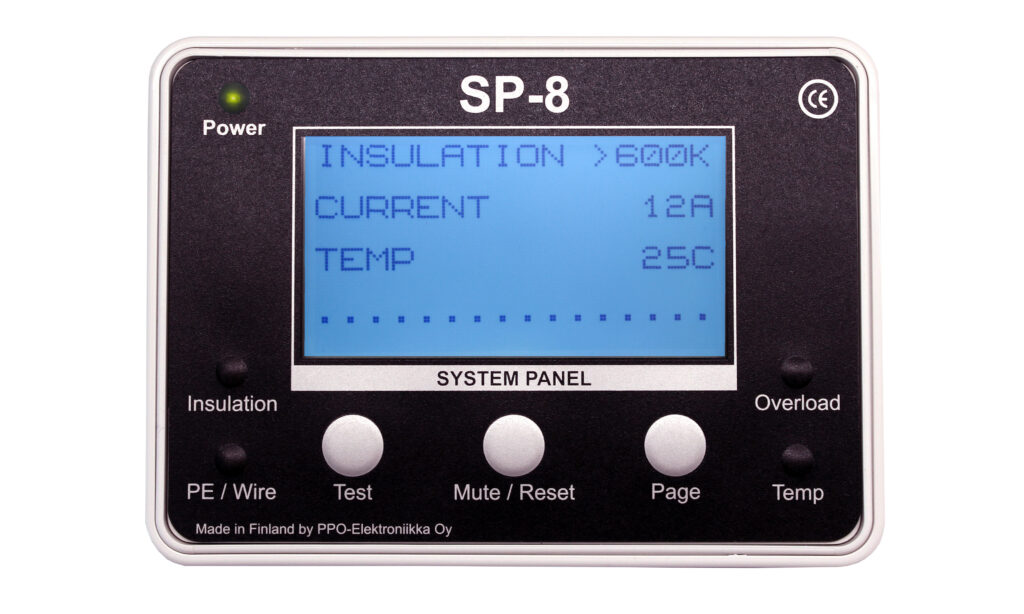

- The insulation-level monitoring system monitors all the electrical devices connected to this transformer. It continuously checks the insulation level of the IT system, the transformer load, temperature, and the continuity of protective earth 24/7.

- The equipment signals faults and issues before dangerous situations arise.

Ensuring critical medical facilities’ electrical safety

Operating rooms are classified as Group 2 medical facilities, where the interfaces of electrically operated medical devices are used for cardiac functions. Faulty electrical equipment can be life-threatening to both patients and staff. Even the slightest equipment failure and leakage current can lead to burns, fire and even severe electric shock. Detecting electrical problems early is a crucial issue in the operating room.

MEV®-8 PPT-presentation

The fifth-generation MEV®-8

The MEV®-8 insulation level monitoring system monitors all the electrical devices connected behind the medical transformer. Units control the insulation level of the IT system, the transformer load, temperature, and the continuity of protective earth 24/7.

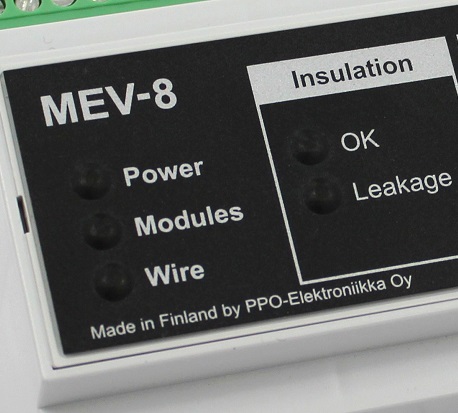

Alarms are indicated via LED lights and relay contacts. MEV-8 operates 230Vac, 50/60Hz.

The solution is also available as a pre-assembled IT power supply system, custom-made to the customer’s specifications. The equipment includes insulation level monitors, a protective isolation transformer and standard central accessories.

MEV®-8 Insulation Monitoring Equipment

MEV-8 insulation level monitoring device

- Monitors the insulation of a floating IT network (leakage current), transformer load (current A) and temperature (°C).

SP-8 System monitoring panel

- Indicates any insulation level alarms, line controller alarms, test lead faults, transformer overloading, and temperature alarms.

LC-8 Line controller

- Monitors the continuity of a floating IT network’s protective earth.

FI-8 Fault locator unit

- Locates any insulation faults in a floating IT network.

Note! We implement comprehensive insulation level monitoring in hospital environments using the devices mentioned above. Our brochure also mentions the devices EV-8, M-8, and AG-8, which can be used as needed, according to each hospital’s specific requirements.

Maximising safety with a new-generation system

The starting point for the new-generation equipment was to transform the context of developing customer needs without compromising technical durability or operability. An essential feature for the international market was an insulation fault positioning feature, based on which we started to create the new insulation monitoring equipment.

Continuous PE-continuity monitoring 24/7

The new-generation equipment includes monitoring of PE continuity. This enables continuous 24/7 monitoring, prevents dangerous situations and decreases the costs of laborious inspections. It complements and ensures the continuity of protective earth between the distribution board and the last socket. If the PE wire breaks, the insulation-level monitoring will not work with that fuse wire.

A missing PE cable may also prevent automatic fuse operation.

Insulation monitoring brings safety, efficiency and cost-savings

- Protects the patients and personnel from electric shocks

- Prevents electrical fires and burns

- Ensures that unnecessary downtime can be avoided

- Ensures that the service life of surgical equipment is extended.

National legislation may not require IT systems and insulation-level monitoring in G2 facilities, but it is seriously worth considering. In addition to increasing safety, it also reduces costs. Notably, the proactive monitoring system eases technical work and ensures that operations are not interrupted. When problems are detected early, hazardous situations during operations can be prevented.

Strong expertise and experience are essential for designing and installing these systems. Technical and clinical staff training is also crucial. Clinical staff need to understand the risks and know how to respond when devices issue alerts. A competent supplier will ensure adequate training and keep the staff up to date.

All our international distributors are professionals in this field and know the needs of critical medical environments. We constantly cooperate with all distributors.

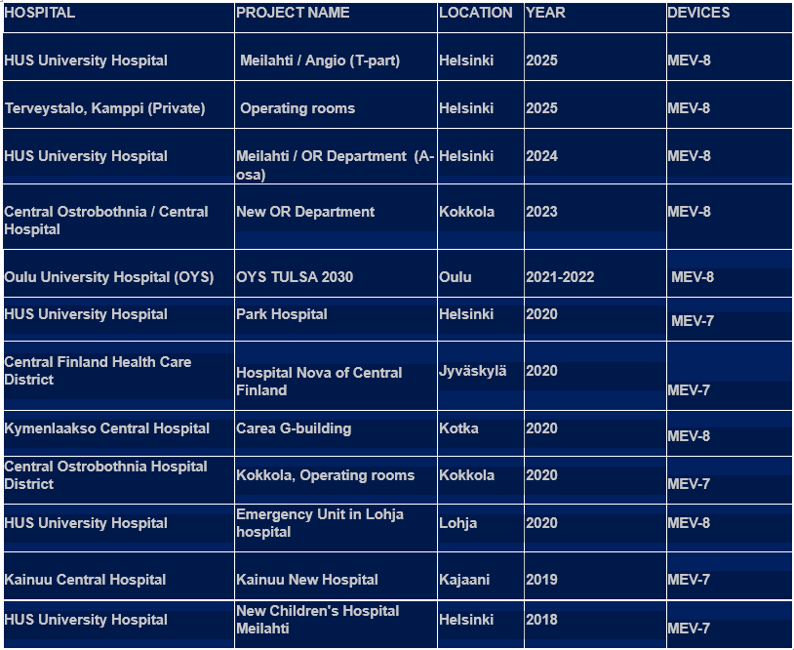

Some examples of our projects in Finland

Finnish hospitals still have older generations of equipment, such as MEV-4, in their operating rooms. This shows that our MEV system is durable, reliable, and long-lasting. Constant quality control and meticulous manufacturing ensure the quality and reliability of our equipment.

We are seeking country representatives, particularly in Europe. We also sell the MEV-8 system directly to hospitals worldwide.

Contact information

Managing Director Timo Ohtonen, +358 9 566 09210, timo.ohtonen@ppo-elektroniikka.fi

More detailed information about techniques

Kimmo Konttinen, tel. +358 9 566 0920 or ppo@ppo-elektroniikka.fi

Our MEV team has strong experience in medical insulation monitoring

Our MEV® team has 43 years of experience in insulation monitoring. PPO-Elektroniikka Oy is a reliable partner. We have received the highest possible Dun & Bradstreet Credit Worthiness Classification and the highest credit rating by Bisnode Finland.

PPO-Elektroniikka Oy is a member of the Association of Finnish Hospital Engineering.

Articles in International Publications

The IFHE Digest. This publication presents perspectives from the hospital and healthcare sector, written by engineers, architects, and facility managers worldwide. It is published annually by the International Federation of Hospital Engineering.

- IFHE Digest 2024 (pages 68-72) Raising safety standards in healthcare facilities

- IFHE Digest 2022 (pages 68-70). Training operating room staff in electrical safety

- IFHE Digest 2019 (pages 19-22). Operating rooms and their electrical safety

- IFHE Digest 2017 (pages 51-53): Insulation monitoring in operating rooms

HEJ Healthcare Estate Journal 9/2020: Insulation monitoring brings safety and cost-savings Pages 69-72 / Authors Mr Timo Ohtonen and Mr Petri Pelkonen

We are happy to give more information about our MEV® Insulation Monitoring System and electrical safety in medical G2 premises:

+358 9 566 0920 or ppo@ppo-elektroniikka.fi.

MEV® is a registered trademark of PPO-Elektroniikka Oy.

MATERIALS

MEV®-8 Insulation Monitoring system (Fifth-generation, since 2020)

MEV-8 Brochure.pdf

MEV-8 Declaration of Conformity

EC Declaration of Conformity by our partner JOPACO Oy