A Finnish health tech company PPO-Elektroniikka Oy has developed the newest, fifth-generation MEV®-8 insulation monitoring system to meet specific requirements and ensure operating room safety. The unique LC-8 Controller Unit monitors Protective Earth wires’ continuity 24/7, guaranteeing safety and continuous, uninterrupted operation without unnecessary downtime.

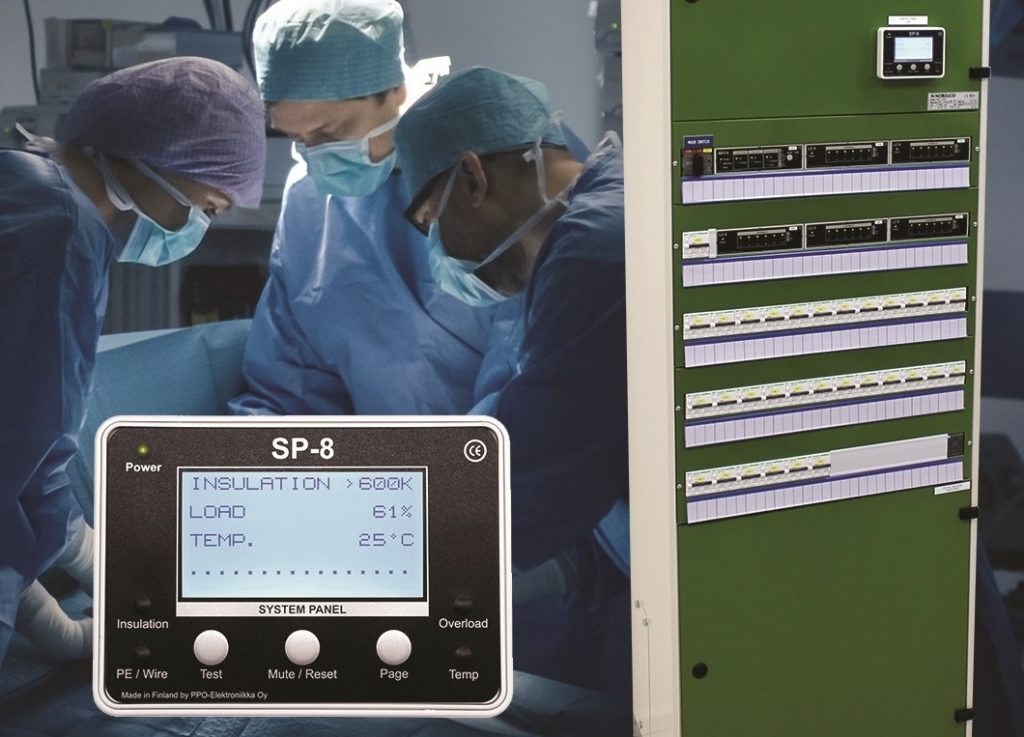

Operating rooms and other G2-classified medical facilities need special monitoring to prevent severe electrical incidents. For that purpose, these premises should have a separate electric grid system for IT and an insulation-level monitoring system, which will anticipate incidents and protect the patients and personnel.

Globally, the national and international standards require insulation level monitoring. However, the electrical safety level of hospitals worldwide is very varied and often incomplete. Generally, insulation monitoring monitors the ungrounded system between an active phase conductor and the earth. The system measures and controls the power supply of IT systems. The units control the insulation level of the IT system and the transformer load and temperature. If the Protective Earth (PE)wire is broken, insulation monitoring is not working. In this situation, patients and staff are in real danger. Even the slightest equipment failure and leakage current can lead to burns, fire and even severe electric shock.

That is why we developed special equipment for monitoring the continuity of protective earth wire under the floating IT network, an essential feature ensuring electrical safety.

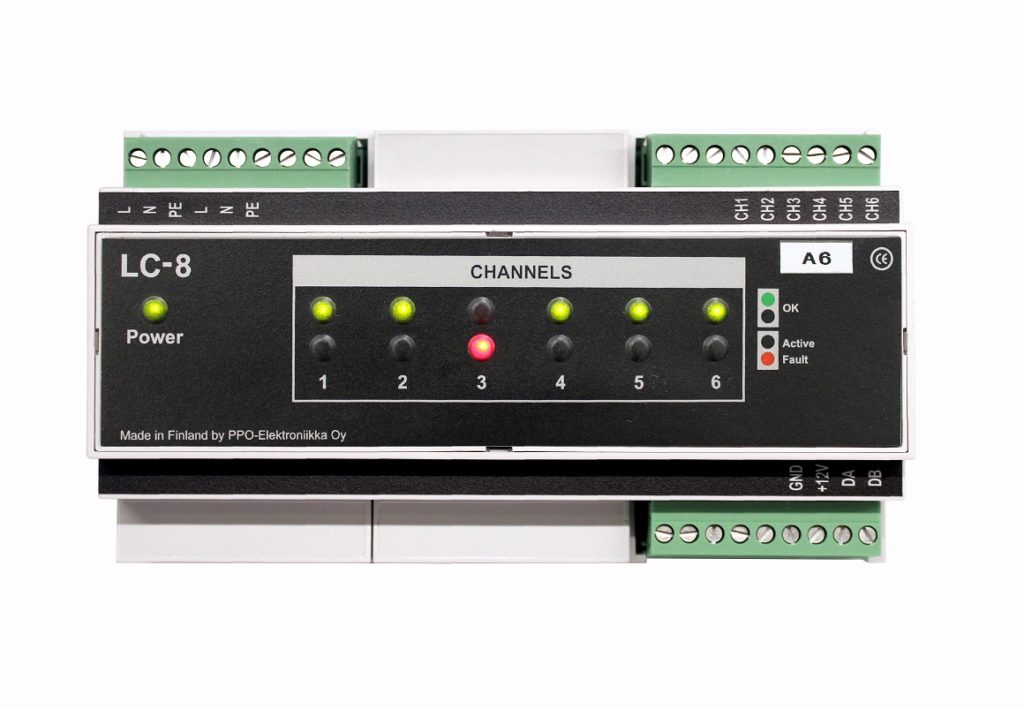

The MEV-8 system’s unique LC-8 Controller Unit

The LC-8 unit monitors PE wires’ continuity 24/7. It complements and ensures the continuity of protective earth between the distribution board and the last socket. The starting point for the new-generation equipment was to transform the context of developing customer needs without compromising technical durability or operability. Our new-generation equipment enables continuous monitoring, prevents dangerous situations and decreases the costs of laborious inspections.

A modern insulation monitoring system guarantees safety

A modern IT system should include insulation fault localization, protective conductor continuity measurement and a fault detection screen in the operating room. In practice, this means that the insulation fault locator indicates the location of the faulty device. Protective conductor continuity measurement ensures that protective earth is used at each socket.

Although technology, practices and safety measures have advanced, there is still a long way to go to achieve an adequate level of electrical safety in operating rooms worldwide. Acquiring a modern IT system with insulation monitoring is a small investment compared to the security and benefits it brings; it is a sustainable solution with a long-life cycle.

Over 41 years of experience in operating rooms

PPO-Elektroniikka Oy was founded to solve operating rooms’ electrical problems as a pioneer in Finland. We specialize in insulation monitoring on medical premises. We have developed five MEV® system generations in close cooperation with the hospitals. Since 1983, we have delivered over 30,000 MEV systems alone in Finland. Today, we export our MEV-8 systems to 23 countries worldwide.

Is your company a professional working in the hospital engineering field?

We are looking for MEV® distributors globally.

To our distributors, we provide remote training, demo equipment and constant support. Our high-quality MEV-8 insulation level monitoring equipment is durable with a long-life cycle. Every MEV-8 system is 100 % tested before delivery. PPO-Elektroniikka Oy is a reliable and agile Finnish partner that does what it promises.